Researchers used computational modeling to design custom-fit PAP masks that were validated against commercially available ones.

Summary: Researchers from Singapore University of Technology and Design, along with Chinese universities and Changi General Hospital, used computational modeling to design custom-fit positive airway pressure (PAP) masks aimed at improving comfort and reducing air leakage for patients with sleep-disordered breathing. By simulating mask fit based on 3D facial scans, the study found that the custom-fit masks outperformed commercially available masks in both comfort and air leakage reduction. The study highlights the potential for computational design to enhance PAP therapy effectiveness and expand into other personalized wearable devices.

Key Takeaways:

- Comfort and Air Leakage: The computationally designed PAP masks provided a better fit, reducing air leakage and improving comfort compared to standard masks.

- Use of 3D Modeling: The research team utilized 3D scans of volunteers’ faces to create custom PAP masks that were tailored to individual facial structures.

- Potential for Broader Application: The study suggests that this computational design approach could be applied beyond PAP masks to other personalized devices, such as oxygen masks and headsets for virtual reality.

Despite the effectiveness of positive airway pressure (PAP) therapy in treating sleep-disordered breathing, PAP therapy is a challenge for many patients in the long term.

“Many patients are intolerant to PAP treatment due to poor mask fit,” says Song Peng, PhD, assistant professor at the Singapore University of Technology and Design, in a release. He highlighted that poor mask fit leads to not only patient discomfort but also air leakage issues that reduce the effectiveness of the treatment.

In response to these challenges, Song led a team comprising researchers from Chinese universities and clinicians from Singapore’s Changi General Hospital to use computational modeling to design PAP masks that optimize comfort while ensuring minimal air leakage.

The study is published in Computers & Graphics.

Modeling a Custom-Fit PAP Mask

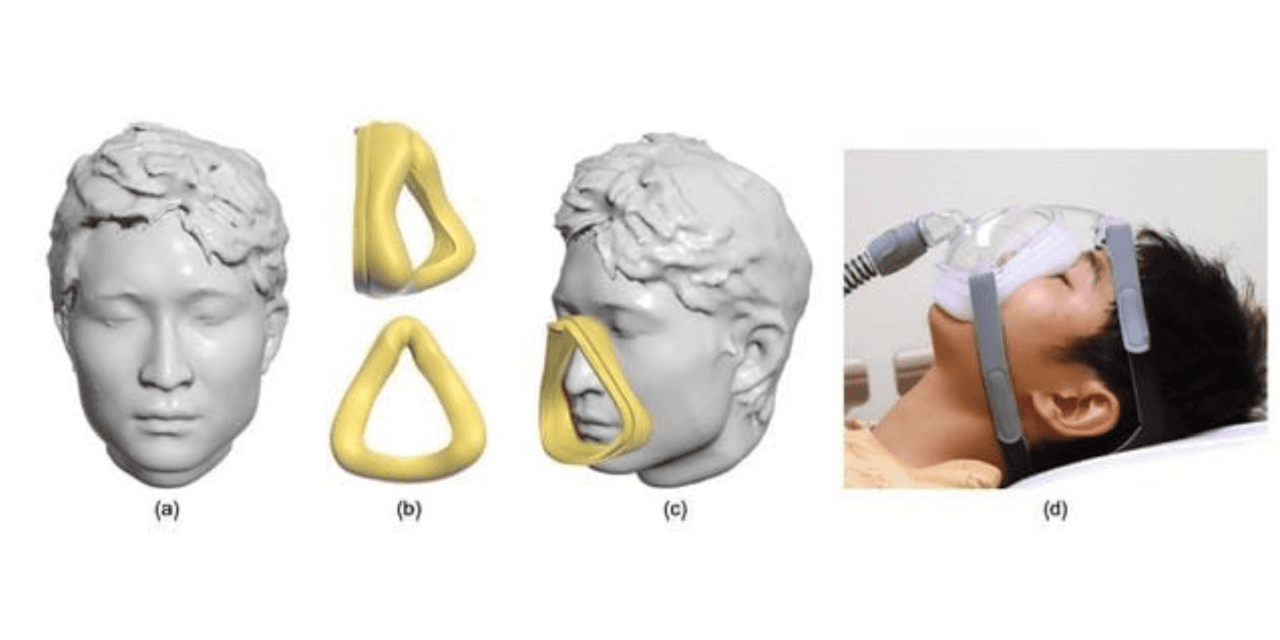

The team first modeled a custom-fit PAP mask by making use of two components to form the mask interface with a patient—the mask cushion that comes in contact with the patient and a connector that joins the cushion to a generic mask frame. Having previously observed that the shape of most commercially available PAP masks can be represented by something known as a “swept surface,” the team then modeled the mask cushion using parameters from a 3D swept trajectory.

To optimize the custom-fit PAP masks for different faces, the team began by scanning the faces of four volunteers to create 3D models. These models were then combined with various PAP mask designs to simulate how each mask would fit in its “equilibrium state,” which represents the mask’s final shape after accounting for the forces applied by the straps and the patient’s facial features.

Due to the computational cost of accurately simulating the mask-face fitting process, the researchers chose to focus on the human face and the mask cushion in their design. The human face was assumed to be rigid, while the mask cushion was treated as a deformable body. By using a method known as quasi-static finite element modeling and creating a tetrahedral mesh for the cushion to support the simulation, the researchers could then simulate a fitted mask.

Evaluating Air Leakage and Comfort

The masks were evaluated based on two key criteria: potential air leakage and comfort level. These factors were quantified by analyzing the forces acting on the mask in its equilibrium state. Thereafter, the team further optimized the mask’s geometry to minimize leakage and maximize comfort while ensuring that the cushion remained easy to fabricate.

The final step in the research was to validate these custom-fit PAP masks against commercially available ones. The volunteers were subjected to PAP therapy with three different masks: a commercially available mask, a baseline custom-fit mask designed by inverting the subject’s face shape, and the team’s custom-fit mask, which was fabricated with a silicone mold. Air leakage was also measured at different air pressures during the treatment.

At the end of the treatment, the volunteers filled in a questionnaire on their experience with the different masks. The results proved highly promising, as the custom-fit masks demonstrated reduced leakage while also being more comfortable than the other masks.

‘A Promising Solution’

Reflecting on the use of design and technology in the study, Song believes his findings will benefit both healthcare professionals and computational design researchers. For respiratory sleep professionals, the custom-fit masks offer a promising solution to the challenges posed by ill-fitting traditional masks. Meanwhile, the computational modeling approach employed by the team could prove interesting to researchers working in computational design and/or computer graphics.

“Our computational design approach closes the design loop in computers—that is, automating the design process—by performing mask evaluation via simulation-based analysis and mask design via optimization,” he says in a release.

The team is eager to expand its research beyond PAP masks and delve into the computational design of personalized wearable artifacts, such as oxygen masks, swimming goggles, and even headsets for virtual and augmented reality platforms.

Photo caption: Given (a) the scanned face model of a subject, researchers developed an optimization-based approach to design a PAP mask cushion that fits the face model. (d) The designed mask cushion is fabricated and assembled with a generic mask frame to form a custom-fit PAP mask for practical use.

Photo credit: Singapore University of Technology and Design